| Uploader: | Dizragore |

| Date Added: | 20 August 2010 |

| File Size: | 44.52 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 99176 |

| Price: | Free* [*Free Regsitration Required] |

CW and Quasi-CW Laser Diode Drivers

Systems Used to Analyze Laser Beams. A current as of January life test graph is shown in Figure 5. Recently, NGCEO has developed a new epitaxial structure to further increase the reliable output power levels of these devices.

We make it simple to buy from top Global suppliers. Duty cycle is the time the current source is on - output current high divided by the total time of the pulse on and off time.

QCW and CW Laser Diodes | Core Technologies | Technologies | SemiConductor Devices

And how this is accomplished without damaging the laser diode. Lasfr degradation rates have been observed in other experiments conducted at NGCEO on the 88x material. They require a special set of specifically designed electronic control elements.

If you purchase a current source desiggn a 2 amp range and the diode requires only 50 mA, pay attention to the current source resolution, it is a function of the total output range. Key Features Output Current: The data sheets will usually also state output current magnitude and voltage, you just have to look for it.

Wavelength Electronics has an excellent video describing their current source designs. We are glad to help!

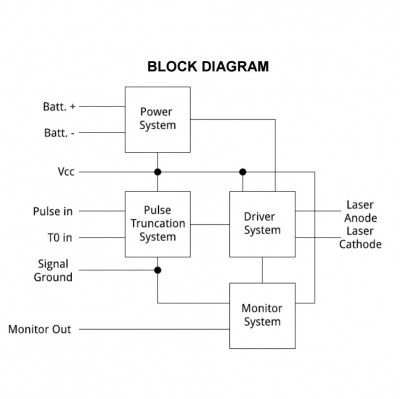

QCW driver for high power laser diodes — lazer for currents up to A. It is good information in block diagram form and easy to understand. This epitaxial structure contained several advances over the previous structure and included a larger waveguide to decrease the optical intensity at the facet and throughout the cavity.

The drive current was increased from A to A over time. Who Makes Laser Diode Drivers?

QCW Driver for High Power Laser Diodes

In order to understand what laser diode drivers are ,aser why they are important, it's important to understand a few of the key featues of laser diode devices. Forward electrical bias across the P-N junction causes the respective holes and electrons from opposite sides of the junction to combine giving off a photon in the process of each combination.

Subscribe to Photonics News. Therefore the life test represents a good approximation of the dioee field use of these diode bars. Particular emphasis is given to the 80x and 88x wavelength bands running at Oaser per bar. A subsequent life test was conducted with an increased sample size in order to compare the performance of the new and standard epitaxial designs.

QCW laser diode bars can operate at higher peak powers than their CW counterparts. As such, minimization of size, weight, power consumption and cost were the primary design drivers. Output accuracy also scales with range if that is important in the application.

NGCEO has spent considerable time and effort developing superior technologies in each regard. These are stand-alone current sources that are housed in an enclosure with a front panel for easy control. Voltage sources bench-top power supplies ramp voltage at turn-on, but the current diodde not controlled.

Quick Look at a Laser Driver Circuit: APDs for Photon Counting.

A quick note about off times in current sources, they are never truly off meaning zero currentbut often are at an output level low enough where the laser diode output is minimal - well below threshold. In addition to life test data, a summary of performance data for each epitaxial structure and each bar design is also presented. These are available in pulsed and CW modes from mA to A or more.

You will find these in many optical labs, clean rooms etc. Reliable operating points are identified for various applications including range finding product lifetimes less than 1 billion shots and industrial machining product lifetimes greater than 20 billion shots.

Comments

Post a Comment